OUR PROCESS.

WE ONLY USE HIGH QUALITY DUCTILE IRON IN OUR PRODUCTS

WHY DUCTILE IRON?

Ductile iron is a family of cast graphitic irons which possess high strength, ductility and resistance to shock. Annealed cast ductile iron can be bent, twisted or deformed without fracturing. Its strength, toughness and ductility duplicate many grades of steel and far exceed those of standard gray irons. Yet it possesses the advantages of design flexibility and low cost casting procedures similar to gray iron.The difference between ductile iron and gray iron is in the graphite

DUCTILE IRON IS NOT A SINGLE MATERIAL BUT IS PART OF A GROUP OF MATERIALS WHICH CAN BE PRODUCED TO HAVE A WIDE RANGE OF PROPERTIES THROUGH CONTROL OF THE MICROSTRUCTURE.

The common defining characteristic of this group of materials is the shape (morphology) of the graphite. In ductile irons, the graphite is in the form of nodules rather than flakes (as in grey iron), thus inhibiting the creation of cracks and providing the enhanced ductility that gives the alloy its name. The formation of nodules is achieved by addition of nodulizing elements, most commonly Magnesium (note Magnesium boils at 1100C and Iron melts at 1500C) and, less often not Cerium (usually in the form of Misch metal). Tellurium has also been used. Yttrium, often a component of Misch metal, has also been studied as a possible nodulizer.

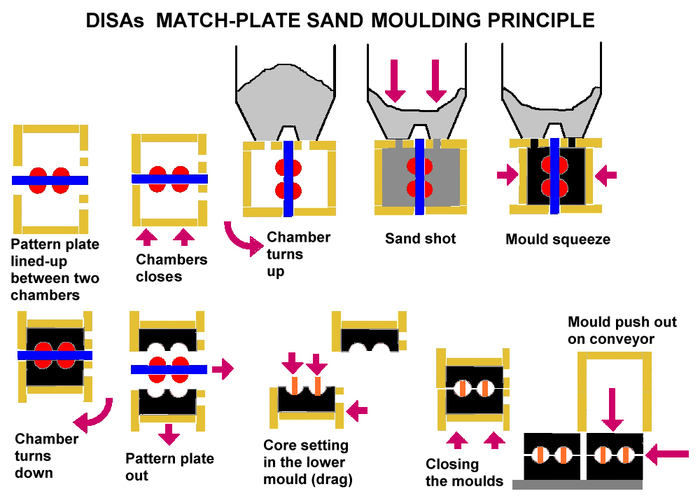

EXAMPLE CASTING PATTERN

PATTERNS ARE USED TO CREATE THE SHAPE IN THE SAND, INTO WHICH MOLTEN METAL WILL BE POURED TO BECOME THE CASTING.

Patterns can be made from metal, wood or plastic. Most patterns are made from aluminum, called match-plates and have a long life before wearing out. Wooden patterns can be used provided the quantities are low and the wall thickness fairly substantial. A casting pattern is a replica of the object to be cast, used to prepare the cavity into which molten material will be poured during the casting process. Patterns are made to exacting standards of construction, according to the quality grade of the pattern being built, and so that they will repeatably provide a dimensionally acceptable casting.